Swiss team develops eco-friendly water-repelling textiles sans PFAS

Insights

- The Swiss Federal Laboratories for Materials Testing and Research has developed an environment-friendly process to generate fibres with a water-repellent finish.

- For the coating, highly cross-linked siloxanes are atomised and activated in a reactive gas.

- They retain their functional properties and enclose the fibres in a water-repellent coating 30 nm thin.

"We use so-called highly cross-linked siloxanes, which create silicone-like layers and—unlike fluorine-containing PFAS—are harmless," Dirk Hegemann from Empa's Advanced Fibres Laboratory in St. Gallen explained in a release from Empa. Siloxanes are organic compounds containing a functional group of two silicon atoms bound to an oxygen atom.

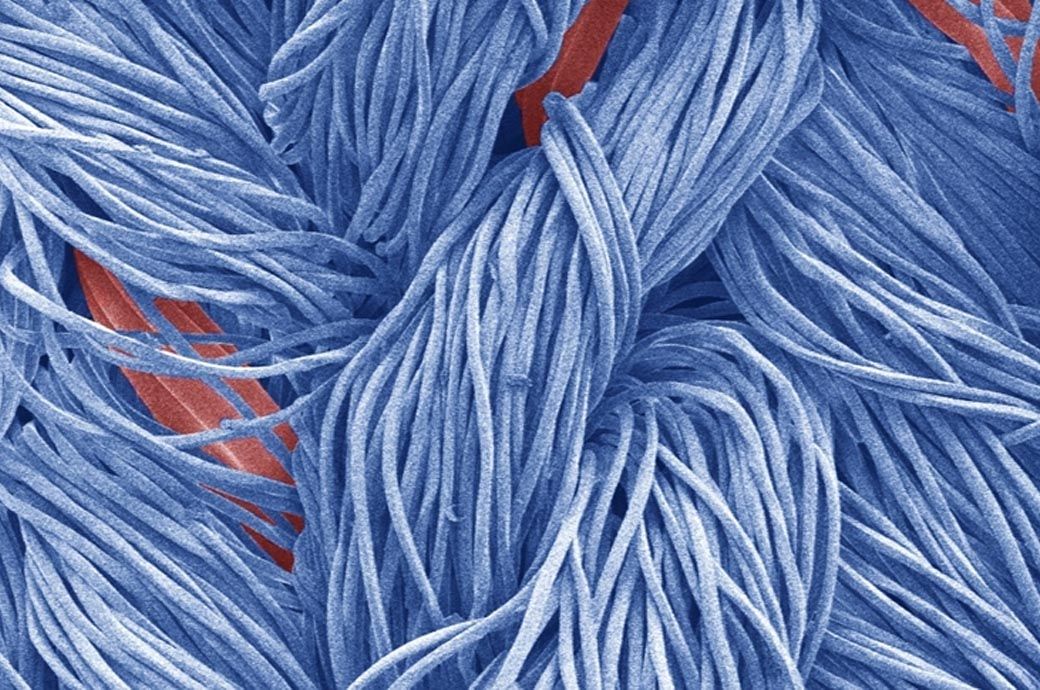

For the coating of textile fibres, the siloxanes are atomised and activated in a reactive gas. They thereby retain their functional properties and enclose the textile fibres in a water-repellent coating that is only 30 nanometres (nm) thin.

Fibres coated this way can then be processed into water-repellent textiles that can be used in garments and upholstery fabrics.

The project is being funded by Swiss innovation agency Innosuisse.

The new process has advantages over conventional wet-chemical processes. Even with complex structured textiles, the seamless distribution of the hydrophobic substances is guaranteed right into all turns of the intertwined fibres.

This is crucial, because even a tiny wettable spot would be enough for water to penetrate into the depths of a pair of swimming trunks, preventing the garment from drying quickly.

"We have even succeeded in permanently impregnating more demanding, elastic fibres with the new process, which was previously not possible," said Hegemann.

In initial laboratory analyses, textiles made from the new fibres are already performing slightly better than conventional PFAS-coated fabrics. They absorb less water and dry faster.

However, the miraculous properties of the fluorine-free coating only really come into their own after the textiles have been washed several times: While the performance of conventional PFAS coatings in stretchy textiles declines considerably after repeated wash cycles, the fluorine-free fibres retain their water-repellent properties, the release said.

Hegemann and his team are now working on scaling up the process into efficient and economically viable industrial processes.

PFAS, per- and polyfluorinated alkyl compounds, are a group of synthetic chemicals that have a wide range of applications due to their ability to repel water, oil and grease.

They have been in use since the 1970s, for example, in the production of functional clothing, fire extinguishers and frying pans.

As carbon-fluorine substances do not degrade but accumulate in the environment and ultimately in the human body, they are referred to as ‘forever chemicals’.

The substances are suspected of causing various health problems in humans and animals, such as cancer, cardiovascular diseases, obesity and developmental disorders. Certain PFAS are already banned.

Fibre2Fashion News Desk (DS)

-Ltd..jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)

.jpg?tr=w-120,h-60,c-at_max,cm-pad_resize,bg-ffffff)